Condition:

New

Machine Type:

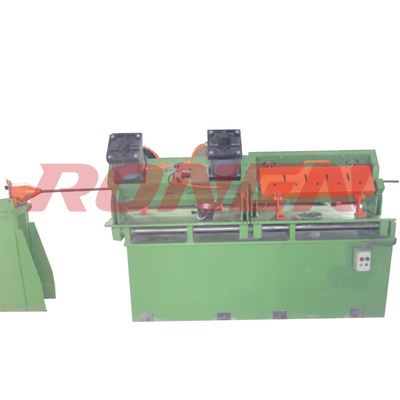

Induction Heating Machine

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

2 years

Core Components:

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump, IGBT

Warranty:

1 Year

Key Selling Points:

High-accuracy

Applicable Industries:

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining

Showroom Location:

Nigeria, Japan, Turkey, Philippines, Indonesia, Pakistan, India, Thailand

After-sales Service Provided:

Engineers available to service machinery overseas, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Power:

10-10000kW

Frequency:

0.1kHz-20000kHz

Application:

annealing,quenching,melting,welding

Daimeter:

9.53

Material:

steel, stainless steel, aluminum, copper, titanium

Type:

Fully Automatic

Voltage:

three phase 220-660V, 50-60HZ

Usage:

Used to build buildings with large loads

Factory:

Yes

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Japan, Ukraine, Nigeria, Turkey, United States, Philippines, Indonesia, Pakistan, India, Thailand

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!